Ceramic Binder Manufacturers

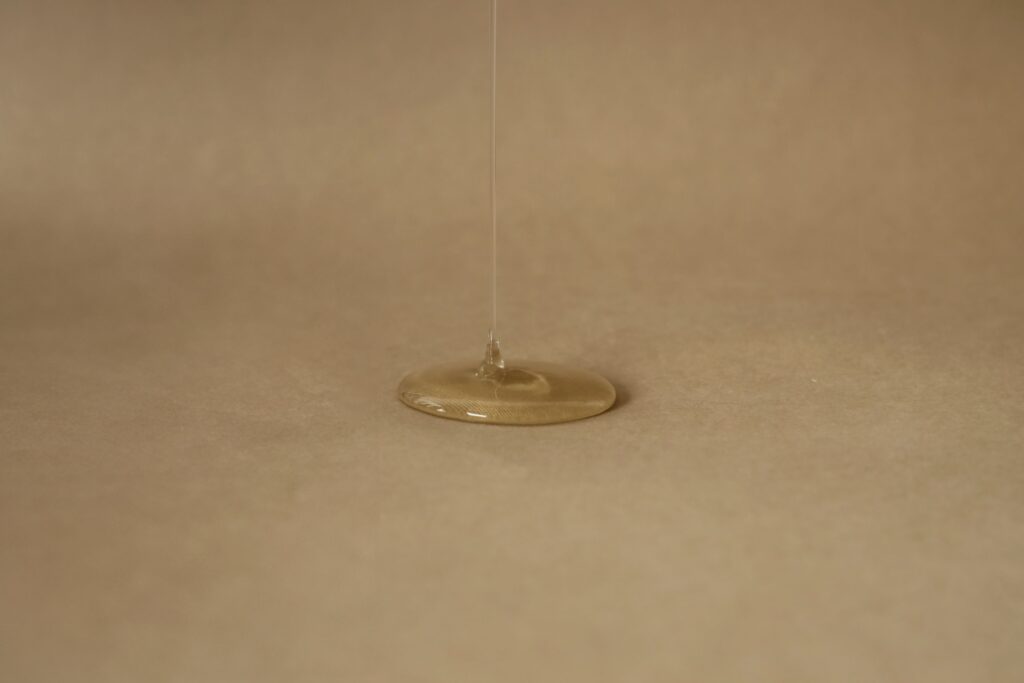

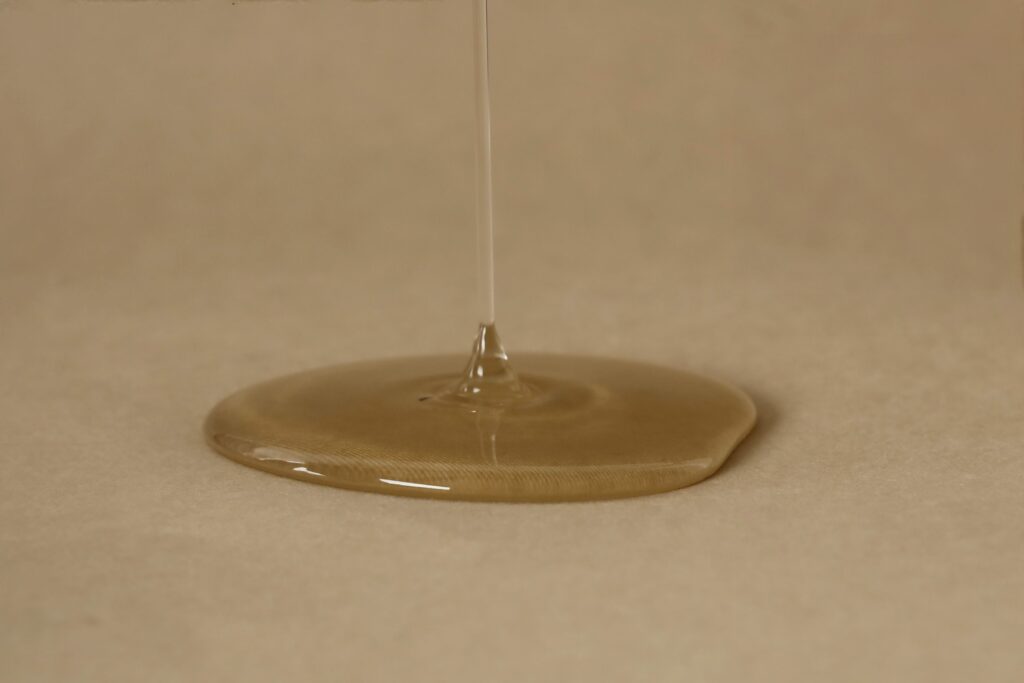

A ceramic binder is a crucial additive in ceramic and tiles manufacturing, providing cohesive strength and plasticity to unfired “green” parts. It holds ceramic particles together during shaping, handling, and drying before high-temperature firing. Key properties include clean burnout (leaving minimal ash), high green strength, improved workability, and enhanced flexibility to prevent cracking.

- High Green Strength

- Low Ash Content

- Improved Workability

- No Negative Interaction

Why Choose our Ceramic Binder

Premium Ceramic Binder Manufacturers

- Superior Green Strength: Our binders are formulated to maximize the mechanical strength of the unfired ceramic body. This critical property minimizes breakage and damage during handling, drying, and machining processes.

- Diverse Ceramic Systems: We offer both organic and inorganic binder options designed for chemical compatibility with various raw materials. Our products integrate seamlessly with common ceramic oxides, glazes, and processing aids without introducing undesirable chemical interactions.

- Improves Extrusion: We engineer our products to enhance the plasticity and flow characteristics of the ceramic mix. This results in smoother shaping and extrusion, allowing for the consistent production of intricate or delicate ceramic components and complex tile designs.

- Residue-Free Burnout: A key feature is the binder's ability to decompose completely during the sintering (firing) cycle. Our formulas guarantee minimal residual ash content, preventing common defects like cracking, blistering, or porosity in the final ceramic product.

- Excellent Adhesion: Our binders promote uniform dispersion and robust adhesion among all ceramic particles and other additives. This consistent particle-to-particle bonding ensures a dense, homogenous green body structure.

- Viscosity Control: The addition of our binder provides precise control over the slurry or paste's viscosity and rheology. This allows manufacturers to maintain optimal flow properties for different forming techniques.

Technical Specifications of Ball Clay

CHEMICAL PROPERTIES

| Binder type | Property |

|---|---|

| Organic | Composed primarily of C, H, and O |

| Inorganic | Composed of various metal oxides |

PHYSICAL PROPERTIES

| Physical Property | PVA | PEG | CMC |

|---|---|---|---|

| Glass Transition Temp | 42 Cent | Varies by MW | 110 Cent |

| Decomposition Temp | 220 Cent | 160 Cent | 250 Cent |

| Typical Molecular Weight | > 1000 Cent | Varies < 8000 | > 10,000 |

Premium Clay Delivered Globally

Get Your Sample Now

Any Queries? We’re Here to Help!